Maganganun EMS don Hukumar da'ira ta Buga

Bayani

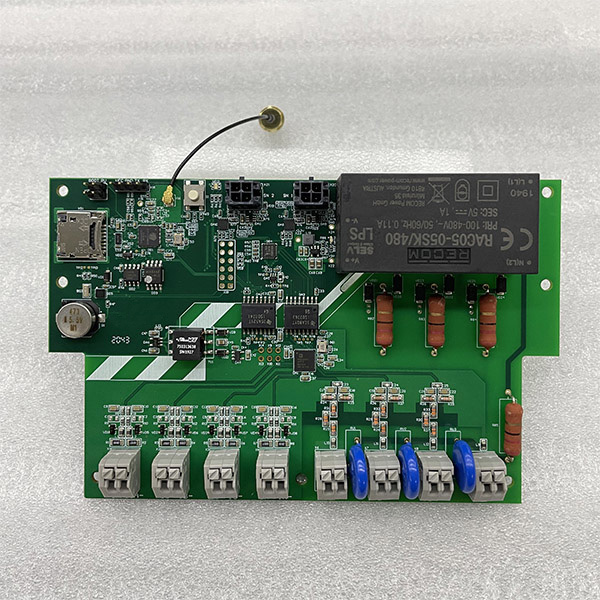

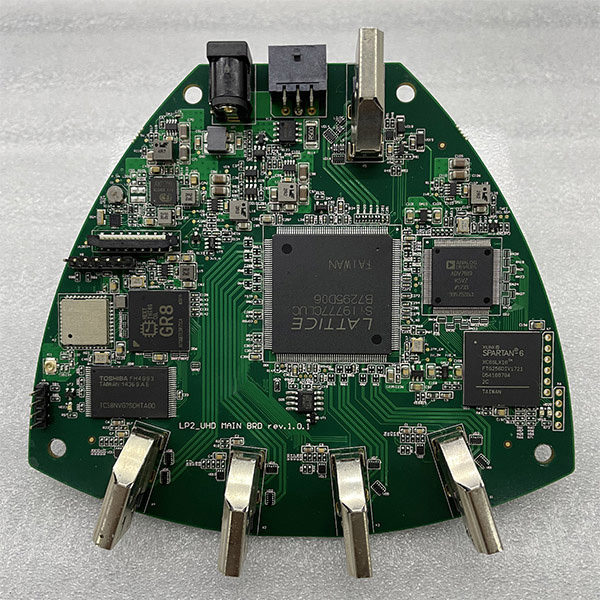

An sanye shi da na'urar SPI, AOI, da na'urar X-ray don layin 20 SMT, 8 DIP, da layin gwaji, muna ba da sabis na ci gaba wanda ya haɗa da fasahohin haɗuwa da yawa da kuma samar da PCBA masu yawa, masu sassaucin ra'ayi. Gidan gwaje-gwajen ƙwararrun mu yana da ROHS, digo, ESD, da na'urori masu gwaji masu ƙarfi & ƙarancin zafi. Duk samfuran ana isar da su ta hanyar kulawa mai inganci. Yin amfani da tsarin MES na ci gaba don sarrafa masana'antu a ƙarƙashin ma'aunin IAF 16949, muna sarrafa samar da inganci da aminci.

Ta hanyar haɗa albarkatu da injiniyoyi, za mu iya ba da mafita na shirin, daga haɓaka shirin IC da software zuwa ƙirar kewayen lantarki. Tare da gwaninta a cikin haɓaka ayyukan a cikin kiwon lafiya da na'urorin lantarki na abokin ciniki, za mu iya ɗaukar ra'ayoyin ku kuma kawo ainihin samfurin zuwa rayuwa. Ta hanyar haɓaka software, shirin, da hukumar kanta, za mu iya sarrafa duk tsarin masana'anta don hukumar, da samfuran ƙarshe. Godiya ga masana'antar mu ta PCB da injiniyoyi, yana ba mu fa'idodi masu fa'ida idan aka kwatanta da masana'anta na yau da kullun. Dangane da samfurin samfurin & ƙungiyar ci gaba, kafa tsarin masana'antu na adadi daban-daban, da ingantaccen sadarwa tsakanin sassan samar da kayayyaki, muna da tabbacin fuskantar kalubale da samun aikin.

| PCBA iyawa | |

| Kayan aiki na atomatik | Bayani |

| Laser marking Machine PCB500 | Alamar alama: 400*400mm |

| Gudun gudu: ≤7000mm/S | |

| Matsakaicin iko: 120W | |

| Q-canzawa, Matsayin Ayyuka: 0-25KHZ; 0-60% | |

| Na'urar bugawa DSP-1008 | Girman PCB: MAX:400*34mm MIN:50*50mm T:0.2~6.0mm |

| Girman Stencil: MAX:737*737mm MIN: 420*520mm | |

| Matsa lamba: 0.5 ~ 10Kgf/cm2 | |

| Hanyar tsaftacewa: bushewa mai bushewa, tsaftacewa rigar, tsaftacewa mai tsabta (mai tsarawa) | |

| Saurin bugawa: 6 ~ 200mm/sec | |

| Daidaiton bugawa: ± 0.025mm | |

| SPI | Ƙa'idar aunawa: 3D Farin Haske PSLM PMP |

| Abun auna: Ƙarar manna mai siyarwa, yanki, tsayi, XY diyya, siffa | |

| Ƙaunar ruwan tabarau: 18um | |

| Daidaitawa: ƙudurin XY: 1um; Babban gudun: 0.37um | |

| Girman girman: 40*40mm | |

| Gudun FOV: 0.45s/FOV | |

| Na'ura mai sauri SMT SM471 | Girman PCB: MAX:460*250mm MIN:50*40mm T:0.38~4.2mm |

| Adadin hawan hawa: 10 spindles x 2 cantilever | |

| Girman naúrar: Chip 0402 (01005 inch) ~ □14mm(H12mm) IC, Mai haɗa (farar jagora 0.4mm), ※ BGA, CSP (Tin ball spacing 0.4mm) | |

| Daidaitaccen hawa: guntu ± 50um@3ó/ guntu, QFP ± 30um@3ó/ guntu | |

| Saurin hawa: 75000 CPH | |

| Na'ura mai sauri SMT SM482 | Girman PCB: MAX:460*400mm MIN:50*40mm T:0.38~4.2mm |

| Adadin hawan hawa: 10 spindles x 1 cantilever | |

| Girman naúrar: 0402 (01005 inch) ~ □ 16mm IC, Mai haɗa (farar jagora 0.4mm), ※ BGA, CSP (Tin ball spacing 0.4mm) | |

| Daidaiton hawa: ± 50μm@μ+3σ (bisa ga daidaitaccen girman guntu) | |

| Saurin hawa: 28000 CPH | |

| HELLER MARK III Nitrogen reflux makera | Yanki: Yankunan dumama 9, yankunan sanyaya 2 |

| Tushen zafi: ɗumbin iska mai zafi | |

| Matsakaicin sarrafa zafin jiki: ± 1 ℃ | |

| Thermal diyya iya aiki: ± 2 ℃ | |

| Gudun Orbital: 180-1800mm/min | |

| Waƙar nisa nisa: 50-460mm | |

| Saukewa: AOI ALD-7727D | Ƙa'idar aunawa: Kyamarar HD tana samun yanayin tunani na kowane bangare na hasken launi uku masu haskakawa akan allon PCB, kuma yana yanke hukunci ta hanyar daidaita hoto ko aiki na ma'ana na ƙimar launin toka da RGB na kowane ma'ana pixel. |

| Abun aunawa: Lalacewar bugu mai siyar, lahani, lahani na haɗin gwiwa | |

| Ƙaunar ruwan tabarau: 10um | |

| Daidaitawa: ƙudurin XY: ≤8um | |

| 3D X-RAY AX8200MAX | Matsakaicin girman ganowa: 235mm*385mm |

| Matsakaicin iko: 8W | |

| Matsakaicin ƙarfin lantarki: 90KV/100KV | |

| Girman mayar da hankali: 5μm | |

| Tsaro (Kashi na hasken haske): 1uSv/h | |

| Wave soldering DS-250 | PCB nisa: 50-250mm |

| Tsawon watsa PCB: 750 ± 20 mm | |

| Gudun watsawa: 0-2000mm | |

| Tsawon yankin preheating: 0.8M | |

| Yawan yankin preheating: 2 | |

| Lambar igiyar ruwa: Wave dual | |

| Injin raba allo | Kewayon Aiki: MAX:285*340mm MIN:50*50mm |

| Daidaitaccen yanke: ± 0.10mm | |

| Gudun Yanke: 0 ~ 100mm/S | |

| Gudun jujjuyawar igiya: MAX:40000rpm | |

| Iyawar Fasaha | ||

| Lamba | Abu | Babban iyawa |

| 1 | tushe abu | Al'ada Tg FR4, High Tg FR4, PTFE, Rogers, Low Dk / Df da dai sauransu. |

| 2 | Solder abin rufe fuska launi | kore, ja, blue, fari, rawaya, purple, baki |

| 3 | Kalar labari | fari, rawaya, baki, ja |

| 4 | Nau'in maganin saman | ENIG, Tin Immersion, HAF, HAF LF, OSP, zinare mai walƙiya, yatsa na zinari, azurfa mai daraja |

| 5 | Max. mai girma (L) | 50 |

| 6 | Max. Girman naúrar (mm) | 620*813 (24"*32") |

| 7 | Max. Girman panel (mm) | 620*900 (24"x35.4") |

| 8 | Max. kauri allon (mm) | 12 |

| 9 | Min. kauri allon (mm) | 0.3 |

| 10 | Hakurin kaurin allo (mm) | T <1.0 mm: +/-0.10mm; T≥1.00mm: +/- 10% |

| 11 | Haƙurin yin rajista (mm) | +/- 0.10 |

| 12 | Min. diamita na rami na inji (mm) | 0.15 |

| 13 | Min. Laser hakowa rami diamita (mm) | 0.075 |

| 14 | Max. al'amari (ta rami) | 15:1 |

| Max. (micro-via) | 1.3:1 | |

| 15 | Min. bakin rami zuwa sararin jan karfe (mm) | L≤10, 0.15;L=12-22,0.175;L=24-34, 0.2;L=36-44, 0.25;L>44, 0.3 |

| 16 | Min. Tsarewar ciki (mm) | 0.15 |

| 17 | Min. Ramin rami zuwa sarari gefen rami (mm) | 0.28 |

| 18 | Min. bakin rami zuwa sararin layin bayanan martaba (mm) | 0.2 |

| 19 | Min. jan karfe na ciki zuwa sapce na bayanan martaba (mm) | 0.2 |

| 20 | Haƙurin yin rajista tsakanin ramuka (mm) | ± 0.05 |

| 21 | Max. Ƙarshen kauri na jan karfe (um) | Layer na waje: 420 (12oz) Layer na ciki: 210 (6oz) |

| 22 | Min. Faɗin alama (mm) | 0.075 (mil 3) |

| 23 | Min. sarari (mm) | 0.075 (mil 3) |

| 24 | Solder abin rufe fuska (um) | layin layi:> 8 (0.3mil) akan jan karfe:> 10 (0.4mil) |

| 25 | ENIG zinariya kauri (um) | 0.025-0.125 |

| 26 | ENIG nickle kauri (um) | 3-9 |

| 27 | Girman azurfar Sterling (um) | 0.15-0.75 |

| 28 | Min. HAL tin kauri (um) | 0.75 |

| 29 | Kaurin kwandon nutsewa (um) | 0.8-1.2 |

| 30 | Kaurin zinari mai kauri mai kauri (um) | 1.27-2.0 |

| 31 | kauri mai yatsa na zinari (um) | 0.025-1.51 |

| 32 | zinari plating nickle kauri (um) | 3-15 |

| 33 | filashin zinari mai kauri (um) | 0,025-0.05 |

| 34 | filashin zinari mai kauri (um) | 3-15 |

| 35 | Hakurin girman bayanin martaba (mm) | ± 0.08 |

| 36 | Max. Mashin solder toshe girman rami (mm) | 0.7 |

| 37 | BGA pad (mm) | ≥0.25 (HAL ko HAL Kyauta: 0.35) |

| 38 | Jurewar matsayi na ruwa V-CUT (mm) | +/- 0.10 |

| 39 | Jurewar matsayi na V-CUT (mm) | +/- 0.10 |

| 40 | Hakurin jurewar kusurwar yatsa na zinari (o) | +/-5 |

| 41 | Haƙurin ƙetare (%) | +/- 5% |

| 42 | Haƙurin shafi (%) | 0.75% |

| 43 | Min. faɗin labari (mm) | 0.1 |

| 44 | Wuta ta kunna wuta | 94V-0 |

| Musamman don Via a cikin samfuran kushin | Girman ramin da aka toshe resin (min.) (mm) | 0.3 |

| Girman ramin da aka toshe resin (max.) (mm) | 0.75 | |

| Resin toshe kauri (min.) (mm) | 0.5 | |

| Resin toshe allon kauri (max.) (mm) | 3.5 | |

| Resin toshe madaidaicin yanayin rabo | 8:1 | |

| Resin toshe mafi ƙarancin rami zuwa sarari (mm) | 0.4 | |

| Za a iya bambanta girman rami a allo ɗaya? | iya | |

| Jirgin saman baya | Abu | |

| Max. Girman pnl (ƙare) (mm) | 580*880 | |

| Max. Girman panel (mm) | 914 × 620 | |

| Max. kauri allon (mm) | 12 | |

| Max. mai girma (L) | 60 | |

| Al'amari | 30:1 ( Min. rami: 0.4 mm) | |

| Faɗin layi / sarari (mm) | 0.075 / 0.075 | |

| Ƙarfin motsa jiki na baya | Ee | |

| Haƙuri na rawar baya (mm) | ± 0.05 | |

| Haƙuri da ramukan dacewa da latsa (mm) | ± 0.05 | |

| Nau'in maganin saman | OSP, azurfar Sterling, ENIG | |

| M allo mai sassauci | Girman rami (mm) | 0.2 |

| Dielectrical kauri (mm) | 0.025 | |

| Girman Panel ɗin Aiki (mm) | 350 x 500 | |

| Faɗin layi / sarari (mm) | 0.075 / 0.075 | |

| Stiffener | Ee | |

| Flex board yadudduka (L) | 8 (4plys na flex board) | |

| Matsakaicin allon allo (L) | ≥14 | |

| Maganin saman | Duka | |

| Flex allo a tsakiya ko na waje Layer | Duka | |

| Musamman don samfuran HDI | Girman ramin hakowa Laser (mm) | 0.075 |

| Max. Dielectric kauri (mm) | 0.15 | |

| Min. Dielectric kauri (mm) | 0.05 | |

| Max. al'amari | 1.5:1 | |

| Girman kushin ƙasa (ƙarƙashin micro-via) (mm) | Girman rami + 0.15 | |

| Girman kushin saman gefen (a kan micro-via) (mm) | Girman rami + 0.15 | |

| Cika tagulla ko a'a (ee ko a'a) (mm) | iya | |

| Ta cikin ƙirar Pad ko a'a (e ko a'a) | iya | |

| An toshe resin rami da aka binne (e ko a'a) | iya | |

| Min. Ta hanyar girman ana iya cika tagulla (mm) | 0.1 | |

| Max. lokutan tari | kowane Layer | |