PCBA shine tsari na hawan kayan lantarki akan PCB.

Muna sarrafa dukkan matakai a wuri guda a gare ku.

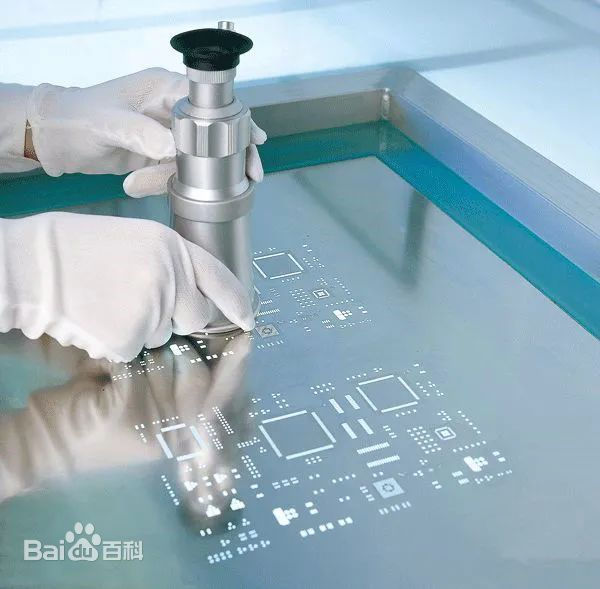

1. Solder Manna Buga

Mataki na farko a cikin taron PCB shine bugu na manna solder akan wuraren kushin allon PCB. Manna mai siyar ya ƙunshi foda da gwangwani kuma ana amfani dashi don haɗa abubuwan da aka gyara zuwa pads a matakai na gaba.

2. Fasahar Motsi (SMT)

Fasaha Motsi (SMT kayan aikin) ana sanya su akan manna ta amfani da bonder. Mai haɗin gwiwa na iya sauri da daidai sanya wani sashi a ƙayyadadden wuri.

3. Sake dawo da siyarwa

PCB tare da abubuwan da aka haɗe ana wucewa ta cikin tanda mai sake fitarwa, inda manna mai siyar ya narke a babban zafin jiki kuma ana siyar da kayan aikin zuwa PCB. Sake dawo da siyarwa shine babban mataki a cikin taron SMT.

4. Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Hulda) da Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kaya (AOI)

Bayan sake dawo da siyarwar, ana duba PCBs na gani ko bincika ta atomatik ta amfani da kayan aikin AOI don tabbatar da cewa an sayar da duk abubuwan da aka gyara daidai kuma basu da lahani.

5. Fasaha-Hole Technology (THT)

Don abubuwan da ke buƙatar fasaha ta hanyar rami (THT), ana shigar da sashin a cikin ramin PCB ko dai da hannu ko ta atomatik.

6. Wave Soldering

PCB na bangaren da aka saka ana wucewa ta na'urar siyar da igiyar igiyar ruwa, kuma na'urar sayar da igiyar igiyar ruwa tana walda bangaren da aka saka zuwa PCB ta hanyar narkakkar solder.

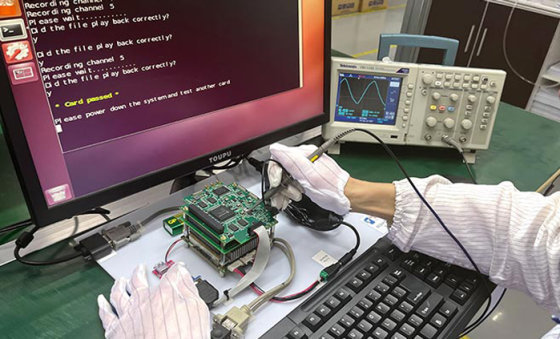

7. Gwajin Aiki

Ana yin gwajin aiki akan PCB ɗin da aka haɗa don tabbatar da cewa yana aiki da kyau a ainihin aikace-aikacen. Gwajin aiki na iya haɗawa da gwajin lantarki, gwajin sigina, da sauransu.

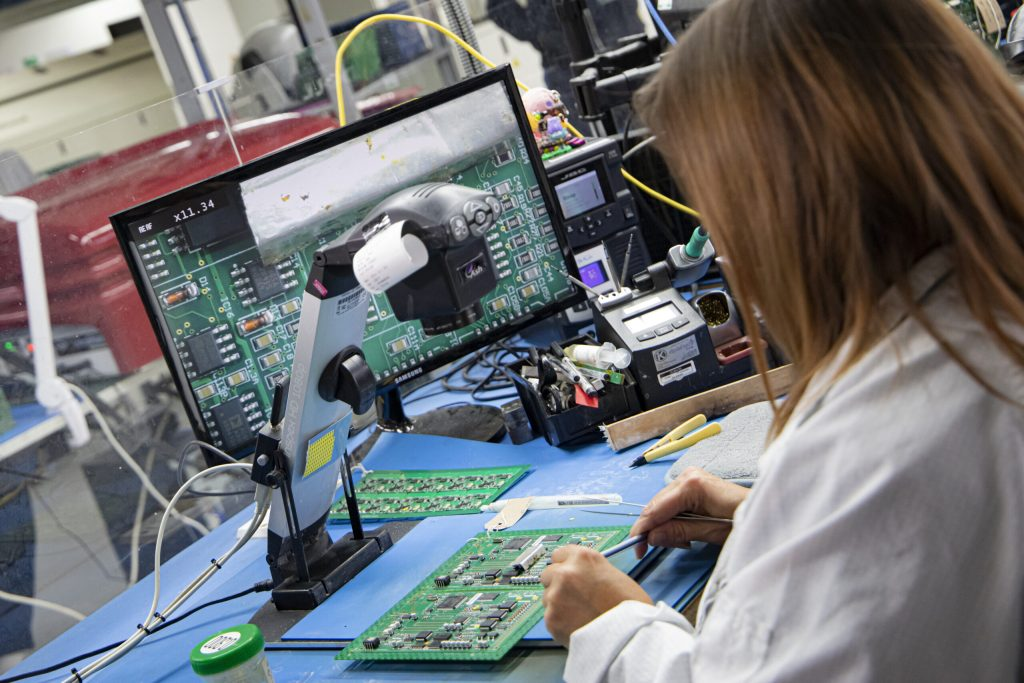

8. Binciken Ƙarshe da Ƙarfafa Ƙarfafawa

Bayan an kammala duk gwaje-gwaje da taro, ana yin gwajin ƙarshe na PCB don tabbatar da cewa an shigar da duk abubuwan da aka gyara daidai, ba tare da lahani ba, kuma daidai da buƙatun ƙira da ƙimar inganci.

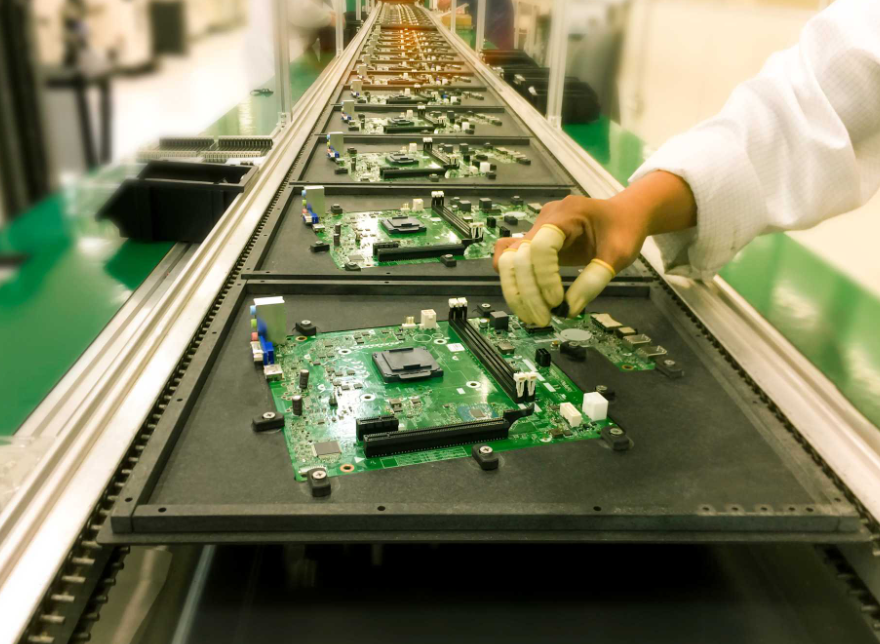

9. Marufi da jigilar kaya

A ƙarshe, PCB ɗin da suka wuce gwajin inganci ana tattara su don tabbatar da cewa ba su lalace ba yayin sufuri sannan a tura su zuwa abokan ciniki.

Lokacin aikawa: Yuli-29-2024