Hauv kev tsim cov qauv tsim, CNC machining thiab silicone pwm ntau lawm yog ob txoj kev siv ntau, txhua qhov muab cov txiaj ntsig sib txawv raws li qhov xav tau ntawm cov khoom thiab cov txheej txheem tsim khoom. Kev tshuaj xyuas cov qauv no los ntawm ntau qhov kev xav-xws li kev ua siab ntev, kev ua tiav ntawm qhov chaw, deformation tus nqi, ntau lawm ceev, nqi, thiab cov khoom sib raug zoo-muab kev pom zoo rau kev xaiv cov txheej txheem tsim nyog.

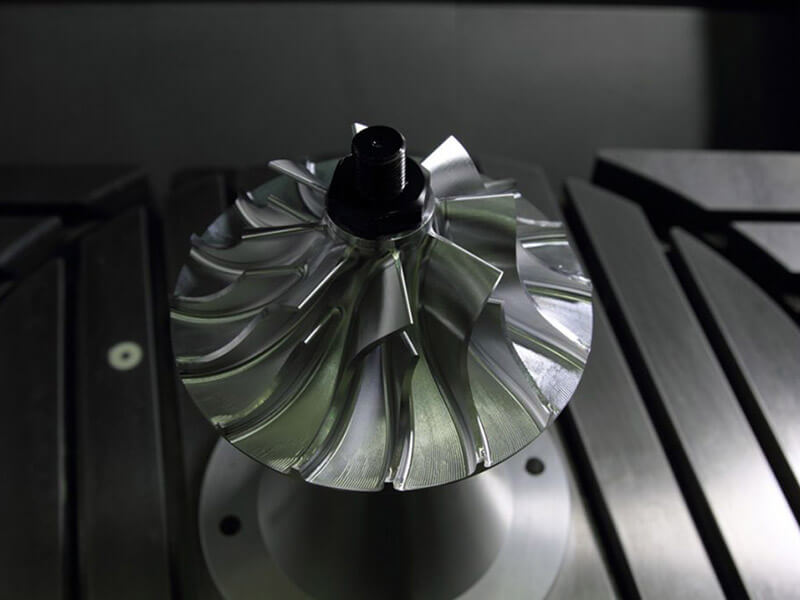

Khoom Tolerances thiab Precision:

CNC machining muaj npe nrov rau nws qhov kev ua haujlwm siab, nrog kev ua siab ntev li ± 0.01 hli, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov geometries nyuaj lossis qhov chaw uas xav tau cov ncauj lus kom ntxaws. Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog rau cov khoom sib dhos lossis cov qauv ua haujlwm uas qhov tseeb yog qhov tseem ceeb. Hauv qhov sib piv, silicone pwm ntau lawm muaj qhov tseeb tsawg dua, nrog rau kev kam rau ua ib puag ncig ± 0.1 hli. Txawm li cas los xij, qhov kev txiav txim siab no feem ntau txaus rau ntau cov neeg siv khoom lossis cov qauv ua ntej.

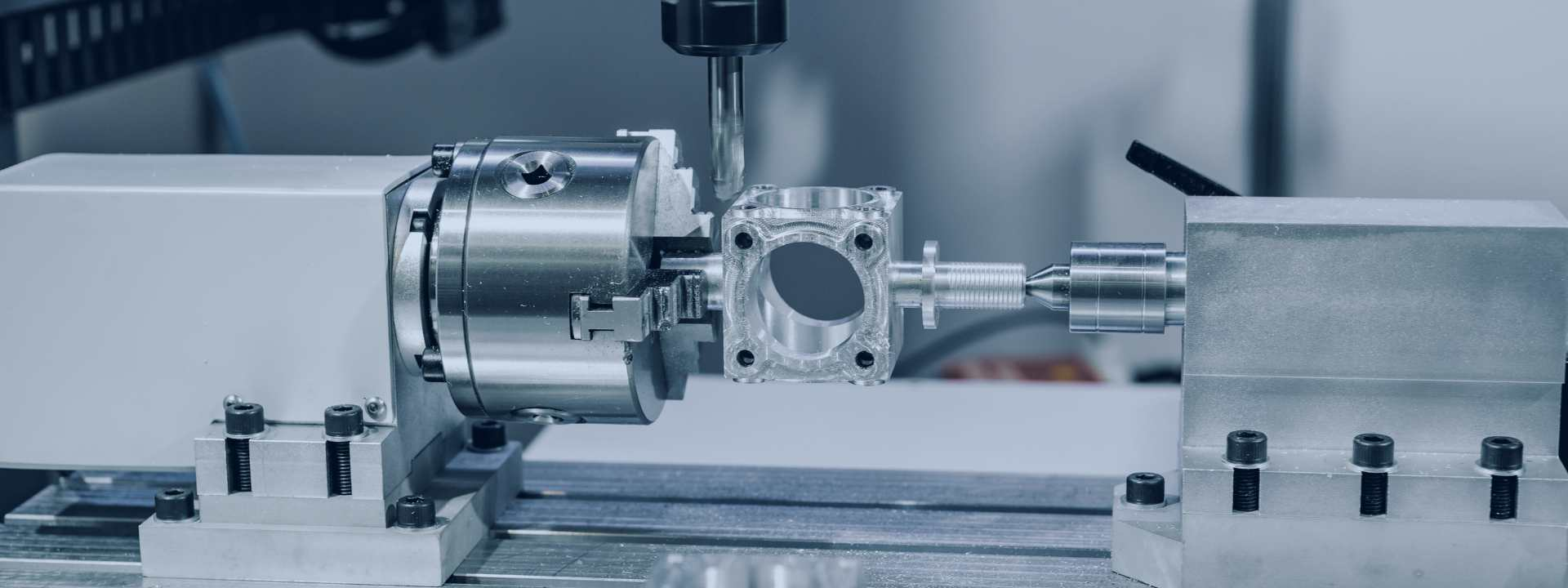

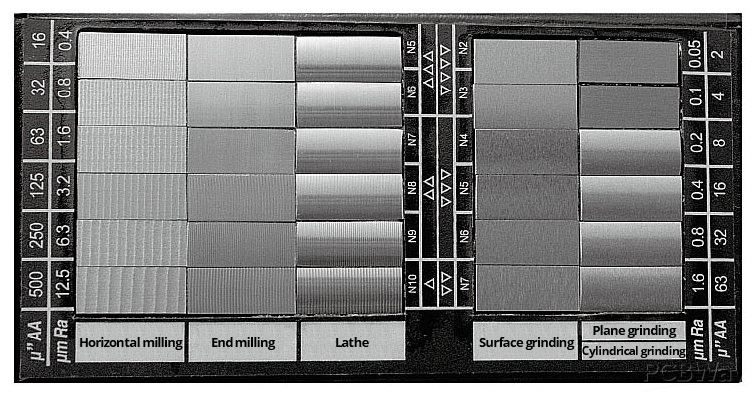

Surface Finish thiab Aesthetic Quality:

CNC machining ua tau zoo heev nto tiav, tshwj xeeb tshaj yog rau cov hlau thiab cov yas nruj. Tom qab ua tiav cov kev xaiv xws li anodizing, hlaws blasting, los yog polishing tuaj yeem txhim kho qhov zoo ntawm qhov chaw, xa cov khoom zoo thiab kev xav, uas yog qhov tseem ceeb rau cov qauv zoo nkauj. Ntawm qhov tod tes, silicone pwm tuaj yeem rov ua cov ntaub ntawv thiab cov ntsiab lus zoo heev tab sis feem ntau yuav tsum tau ua tiav theem nrab kom ua tiav qhov sib piv ntawm qhov sib luag, tshwj xeeb tshaj yog nrog cov ntaub ntawv softer xws li rubbers lossis elastomers.

Deformation thiab kev ua haujlwm zoo:

CNC machining, ua cov txheej txheem rho tawm, muab cov qauv kev ntseeg siab nrog tsawg deformation vim tias tsis muaj cua sov lossis kho kev koom tes. Qhov no ua rau nws tsim nyog rau qhov chaw uas xav tau kom muaj kev ruaj ntseg, tshwj xeeb tshaj yog nyob rau hauv kev thauj khoom lossis kev ntxhov siab. Silicone pwm ntau lawm, txawm li cas los xij, suav nrog cov ntaub ntawv pov thawj uas tuaj yeem ua rau me ntsis shrinkage lossis warping thaum lub sijhawm kho, uas tuaj yeem cuam tshuam qhov tseeb ntawm cov khoom kawg, tshwj xeeb tshaj yog rau cov khoom loj lossis tuab.

Production Speed thiab Lead Time:

Thaum nws los txog rau kev tsim khoom ceev, silicone molding muaj qhov zoo tshaj plaws hauv kev tsim ntau yam qauv hauv lub sijhawm luv. Thaum cov pwm tau npaj lawm, ntau lawm tuaj yeem nce sai, ua rau nws zoo tagnrho rau kev tsim khoom me me thiab kev sim ua lag luam. CNC machining, thaum qeeb qeeb rau cov ntim ntau lawm, muaj lub sijhawm hloov pauv sai rau ib qho lossis tsawg qhov chaw, ua rau nws xaiv zoo dua rau cov qauv pib lossis thaum tsim cov qauv tsim ntau zaus.

Kev siv nyiaj thiab khoom siv:

CNC machining feem ntau suav nrog cov nqi siab dua vim yog cov nqi ntawm cov khoom siv raw (tshwj xeeb yog hlau) thiab lub sijhawm siv lub tshuab yuav tsum tau ua rau qhov nyuaj. Tsis tas li ntawd, cov txheej txheem CNC tuaj yeem ua rau cov khoom siv khib nyiab, tshwj xeeb tshaj yog nyob rau hauv kev tsim cov khoom lag luam uas tseem ceeb ntawm cov khoom raug tshem tawm. Hauv qhov sib piv, silicone pwm ntau lawm yog tus nqi ntau dua rau cov ntim qis, vim cov khoom siv qis dua, thiab cov pwm tuaj yeem rov qab siv dua. Txawm li cas los xij, silicone molding yuav tsum tau ua ntej kev nqis peev, uas tej zaum yuav tsis tsim nyog rau qhov tsawg kawg nkaus los yog ib qho piv txwv.

Hauv kev xaus, CNC machining thiab silicone pwm tsim ob qho tib si ua lub luag haujlwm tseem ceeb hauv kev tsim qauv, txhua qhov tsim nyog rau ntau theem ntawm kev tsim khoom. CNC machining yog nyiam rau high-precision, rigid, thiab cov ncauj lus kom ntxaws prototypes, thaum silicone molding muaj ib tug ceev, ntau nqi-zoo tshuaj rau saj zawg zog, ergonomic, los yog ntau chav tsev ntau lawm. Kev nkag siab txog cov kev cai tshwj xeeb ntawm tus qauv, suav nrog kev ua siab ntev, qhov ua tiav, ntim ntau lawm, thiab cov khoom xav tau, yog qhov tseem ceeb hauv kev xaiv txoj hauv kev rau koj qhov project.

Post lub sij hawm: Oct-23-2024