OEM Solutions rau pwm Fabrication

Kev piav qhia

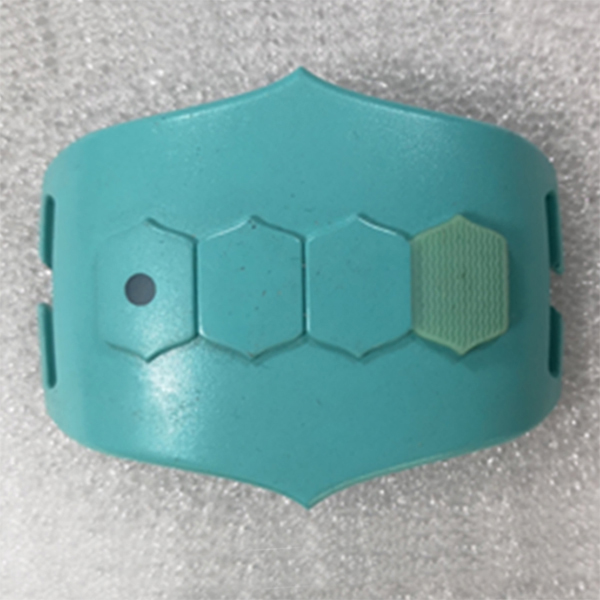

Rau yas pwm, cov txheej txheem tseem ceeb suav nrog kev txhaj tshuaj pwm, extrusion pwm, thiab cov pwm pwm. Ib qho ntawm cov yas ntawm cov duab sib txawv thiab qhov ntau thiab tsawg tuaj yeem tsim los ntawm kev sib koom ua ke ntawm kev hloov pauv hauv cov kab noj hniav thiab cov tub ntxhais ntawm pwm thiab pab pawg. Peb tau tsim cov vaj tsev yas rau cov khoom siv hauv kev tswj hwm kev lag luam, NB-IoT, Beacon, thiab cov neeg siv khoom siv hluav taws xob los ntawm kev siv cov khoom siv ABS, PA, PC, thiab POM.

Rau stamping pwm,nws yog cov pwm tsim cov khoom siv hauv tsev, kev sib txuas lus, thiab tsheb. Vim yog cov ntaub ntawv tshwj xeeb uas siv rau ntawm cov pwm, nws muaj peev xwm tau txais cov hlau stamping qhov chaw nrog cov phab ntsa nyias, lub teeb yuag, zoo rigidity, siab nto zoo, thiab cov duab nyuaj dua li lwm txoj hauv kev. Qhov zoo yog ruaj khov thiab cov txheej txheem ua tau zoo.

Rau tuag casting pwm,nws yog ib qho cuab yeej rau casting hlau qhov chaw. Aluminium alloys yog dav siv nyob rau hauv non-ferrous alloy tuag castings, ua raws li zinc alloys. Peb ua cov khoom siv nrog cov khoom siv aluminium alloy, uas tau sib sau ua ke rau hauv kev tswj xyuas kev nkag mus rau pej xeem ib puag ncig thiab cov prospector rau kev kuaj xyuas kev ruaj ntseg.

Nrog ntau tshaj kaum xyoo ntawm kev paub txog kev tsim pwm, peb tuaj yeem muab cov kev pabcuam los ntawm pwm tsim rau kev tsim vaj tsev.

| Pwm muaj peev xwm | |

| Cov khoom siv tsis siv neeg | Kev piav qhia |

| Yas txhaj tshuab: | 450 T: 1 set; 350T: 1set; 250T: 2sets; 150T: 15sets; |

|

| 130T: 15sets; 120T: 20sets; 100T: 3sets; 90t:5 ua. |

| Tempo tshuab luam ntawv: | 3set ib |

| Silkscreen luam ntawv tshuab: | 24 sets |

| Tshaj-txhaj rau yas, kho vajtse painting, UV / PU painting, conductive painting, sandblast, oxidation, drawbench. | |

| Over-spraying tshuab: | Static kua / hmoov painting, UV curing, tsis siv neeg txau kab, DISK painting chav, ziab rauv. |

| Automatic equipments: | Tsis siv neeg cov kab ntau lawm rau txhua yam me me, lub xov tooj ntawm tes plhaub thiab lub koob yees duab npog, cov kab tsis muaj plua plav ntawm 0.1 lab qib, PVC kis kab, cov kab ntxuav. |

| Ib puag ncig khoom siv: | Dej-ntxuav painting tank, hmoov painting tank, cua-siv chav, dej khib nyiab / khib nyiab pov tseg, UV packing tshuab. |

| Hluav taws xob cov khoom siv: | Txee qhov cub, qhov cub kub ntawm cov roj diesel, Cua kub qhov cub, Gas Infrared Cub, Roj Qhov cub, Qhov cub hom ziab, UV Curing Cub, Kub kub qhov cub dej txiav rauv, tshuab ntxhua khaub ncaws, ziab qhov cub |

Cov duab Hoobkas