In PCB design, the potential for sustainable production is increasingly critical as environmental concerns and regulatory pressures grow. As PCB designers, you play a crucial role in promoting sustainability. Your choices in design can significantly reduce environmental impact and align with global market trends towards eco-friendly electronics. Below are key considerations for you to consider in your responsible role:

Material Selection:

One of the primary factors in sustainable PCB design is the choice of materials. Designers should opt for eco-friendly materials that minimize environmental harm, such as lead-free solder and halogen-free laminates. These materials not only reduce environmental impact but also perform comparably to their traditional counterparts. Compliance with directives like RoHS (Restriction of Hazardous Substances) ensures that the use of hazardous substances like lead, mercury, and cadmium is avoided. Additionally, selecting materials that can be easily recycled or repurposed can significantly reduce the long-term environmental footprint of the product.

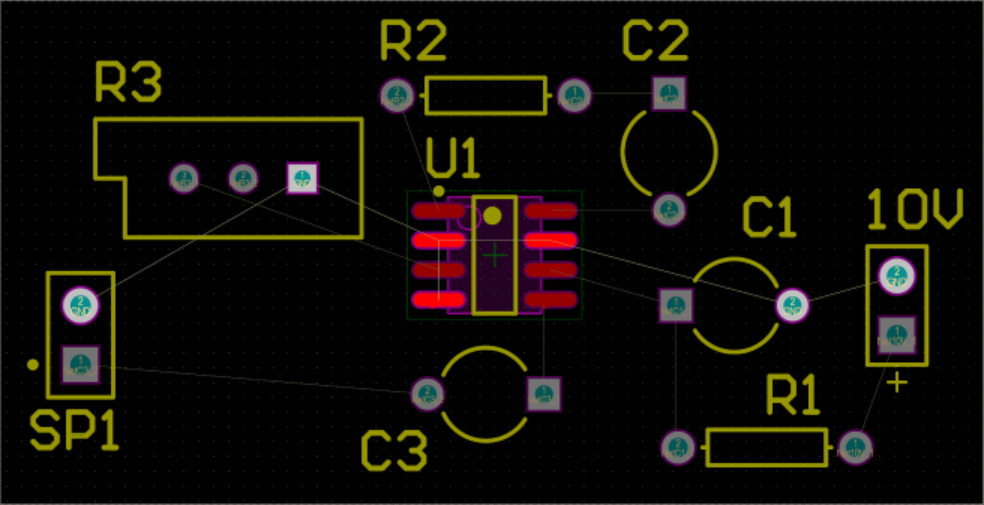

Design for Manufacturability (DFM):

Sustainability should be considered at the early stages of design through Design for Manufacturability (DFM) principles. This can be achieved by simplifying designs, reducing the number of layers in the PCB, and optimizing material usage. For instance, reducing the complexity of the PCB layout can make it easier and faster to manufacture, thereby reducing energy consumption. Similarly, using standard-sized components can minimize material waste. Efficient design can also lower the amount of raw material required, which directly impacts the sustainability of the entire production process.

Energy Efficiency:

Energy consumption during the manufacturing process is a significant factor in a product’s overall sustainability. Designers should focus on reducing energy usage by optimizing trace layouts, minimizing power loss, and using components that require lower energy during both operation and production. Energy-efficient designs not only reduce the environmental impact but also improve product performance and lifecycle.

Lifecycle Considerations:

Designing PCBs with the entire product lifecycle in mind is a thoughtful and considerate approach that promotes sustainability. This includes considering the ease of disassembly for recycling, repairability, and the use of modular components that can be replaced without discarding the entire product. This comprehensive view of the product’s life promotes sustainability and reduces e-waste, making your design process more thoughtful and considerate.

By integrating these sustainable practices into PCB design, manufacturers can not only meet regulatory requirements but also contribute to a more environmentally friendly electronics industry, promoting long-term sustainability throughout the product lifecycle.

Post time: Oct-07-2024