In the world of modern manufacturing, custom injection molding has become a cornerstone of scalable, high-precision production. Whether for medical devices, consumer electronics, industrial components, or automotive parts, this manufacturing process offers an unmatched combination of consistency, cost-efficiency, and versatility—especially when tailored to the specific needs of a product.

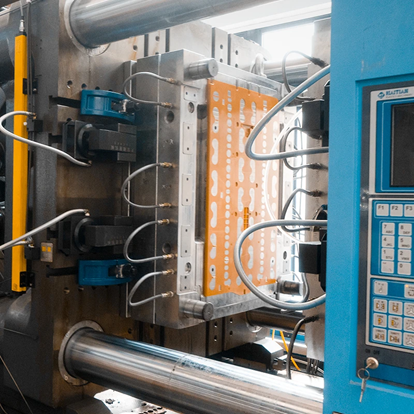

Injection molding works by injecting molten material—typically plastic—into a precisely designed mold cavity. Once cooled, the material solidifies into the final part, replicating even the most intricate details of the mold with exceptional accuracy. For companies seeking high-volume production with tight tolerances and repeatable quality, injection molding is often the preferred solution.

Where custom injection molding sets itself apart is in the ability to create molds and parts that are fully tailored to the product’s design, performance requirements, and aesthetic vision. Instead of relying on off-the-shelf solutions, businesses can achieve complete control over material selection, surface finish, part geometry, color, and functional features.

At Minewing, we offer end-to-end custom injection molding services—from design for manufacturability (DFM) and mold fabrication to sample verification and final production. Our engineering team works closely with clients at every stage to optimize part design, select the most suitable resins or composites, and ensure that every detail aligns with performance and durability requirements.

One of the greatest strengths of custom injection molding lies in its adaptability. Whether the client needs a single prototype mold for testing or a multi-cavity steel mold for mass production, the process can be scaled accordingly. Additionally, secondary processes such as overmolding, insert molding, and surface texturing can be integrated to further enhance product functionality and appeal.

In a global market that values speed, reliability, and innovation, partnering with a capable and experienced injection molding provider is key to success. Minewing brings over two decades of experience in custom manufacturing, supporting clients from prototyping through production with full supply chain support, quality control, and international certification compliance.

From idea to reality, our Custom Injection Molding Service helps bring your vision to life—accurately, efficiently, and at scale.

Post time: Apr-13-2025