The PCB design process significantly influences the downstream stages of manufacturing, particularly in material selection, cost control, process optimization, lead times, and testing.

Material Selection: Choosing the right substrate material is crucial. For simple PCBs, FR4 is a common choice, offering a balance between cost and performance. However, complex boards like HDI (High-Density Interconnect) may require advanced materials like Teflon, affecting both cost and performance capabilities. A designer’s early decisions about materials dictate overall production feasibility and expenses.

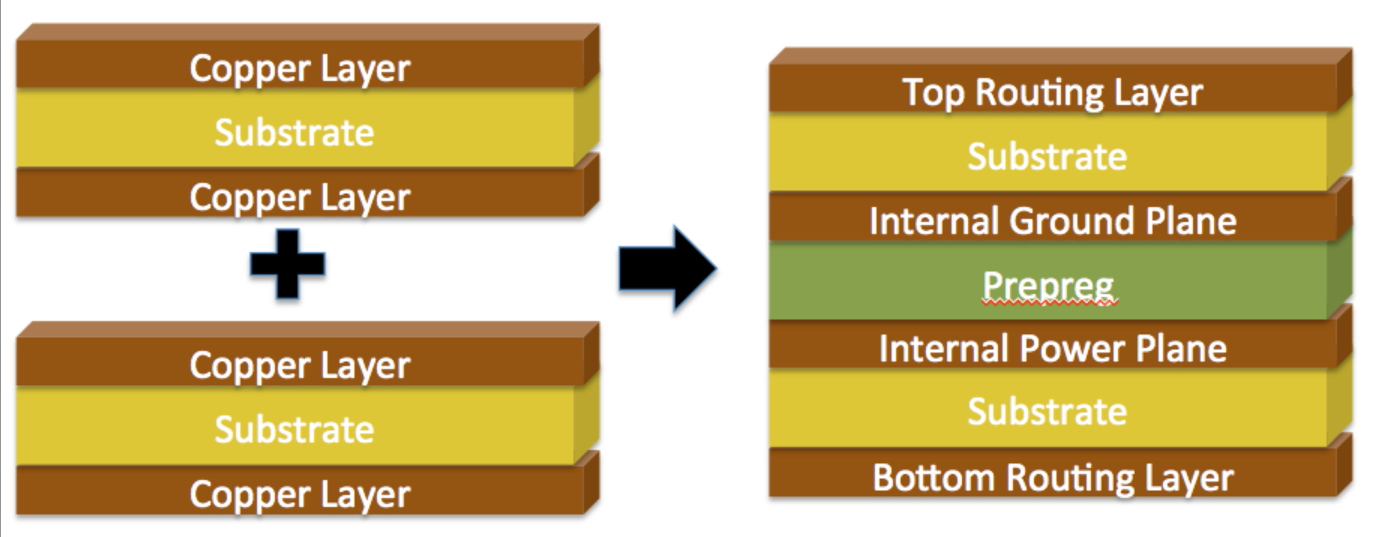

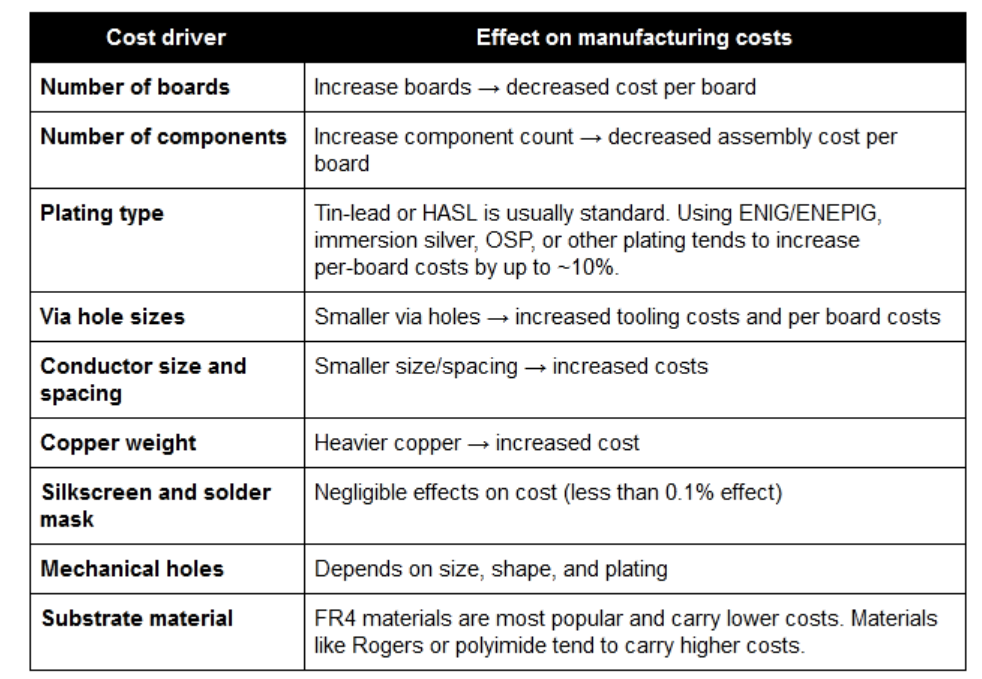

Cost Control: Effective PCB design can help reduce costs by minimizing the number of layers, avoiding excessive use of vias, and optimizing the board’s dimensions. For complex boards, adding too many intricate layers can drive up manufacturing costs. Thoughtful design reduces the waste of expensive materials.

Process Optimization: Simple boards may follow a straightforward manufacturing process, but complex designs like HDI involve more advanced techniques, such as laser drilling for microvias. Ensuring that the design aligns with the factory’s capabilities early on improves yield and reduces production errors.

Lead Time: A well-optimized design, with clearly defined stack-ups and minimal revisions, allows manufacturers to meet deadlines efficiently. Complex PCBs may take longer to produce due to advanced processes, but a clear design helps mitigate potential delays.

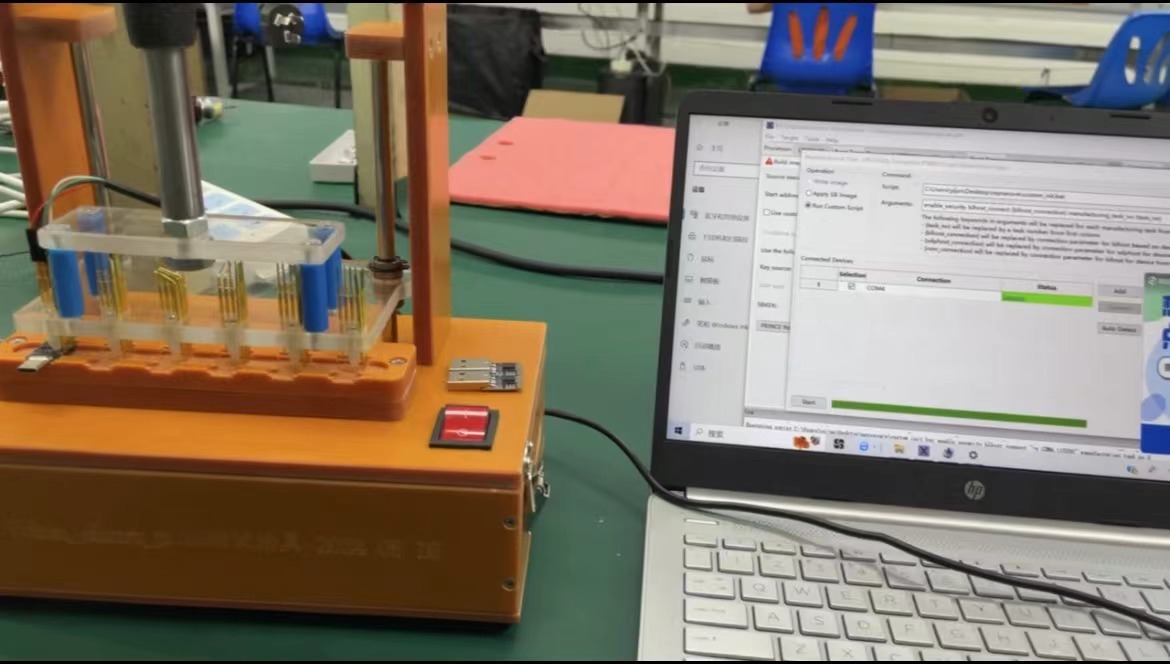

Testing: Finally, the design must accommodate testing procedures, including test points and accessibility for in-circuit testing (ICT). Well-planned designs allow for quicker, more accurate testing, ensuring product reliability before full-scale production.

In conclusion, the PCB design process plays a pivotal role in shaping the efficiency and success of subsequent manufacturing stages. Proper material selection aligns with both performance requirements and cost constraints, while thoughtful design practices contribute to process optimization and cost control. For complex boards like HDI, early design decisions involving advanced technologies can significantly impact manufacturing workflows and lead times. Additionally, integrating testing considerations into the design phase ensures robust quality assurance. A well-executed PCB design ultimately enables manufacturers to meet production demands with precision, efficiency, and reliability.

Post time: Oct-07-2024