In today’s fast-paced product development environment, rapid prototyping has become an essential process for companies aiming to bring their ideas to market faster, with greater precision and flexibility. As industries from consumer electronics to medical devices and automotive technologies strive to reduce development cycles and improve product quality, rapid prototyping stands out as a game-changing solution.

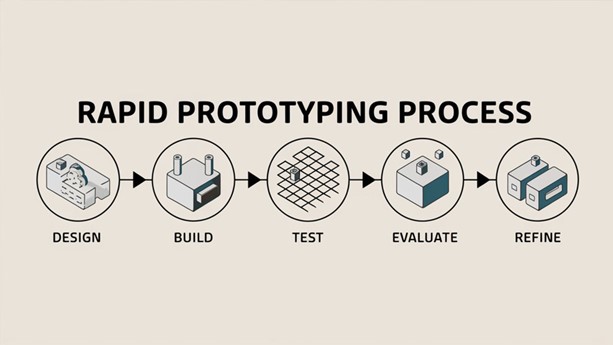

At its core, rapid prototyping is a group of techniques used to quickly fabricate a scale model or functional version of a physical part or assembly using three-dimensional computer-aided design (CAD) data. Unlike traditional prototyping methods, which can take weeks or even months, rapid prototyping allows for the creation of parts in a matter of days—or even hours—depending on complexity and materials.

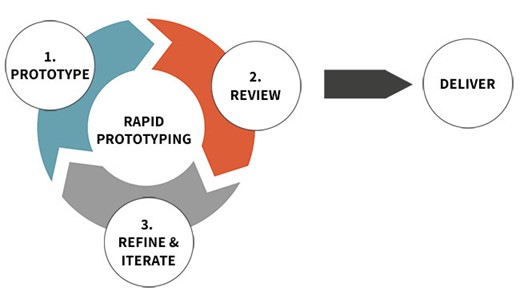

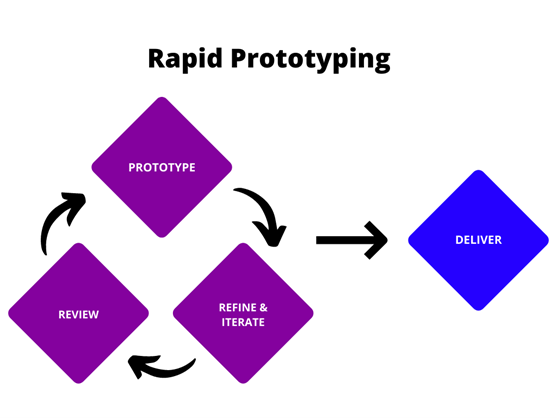

One of the key benefits of rapid prototyping is the ability to perform early testing and validation. Engineers and designers can physically interact with their concepts, test form and fit, and evaluate functionality long before committing to full-scale production. This iterative process reduces design flaws, shortens lead times, and ultimately lowers development costs.

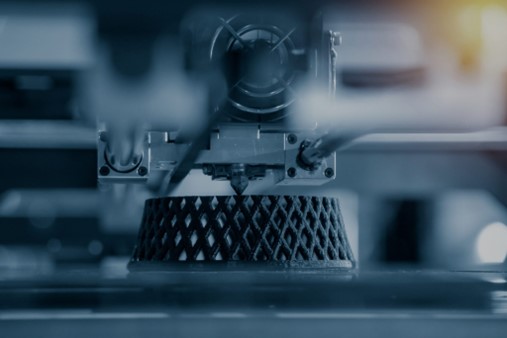

Additive manufacturing technologies such as 3D printing, stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM) are frequently used in rapid prototyping. Each method offers distinct advantages depending on the desired material properties, tolerances, and production goals. Increasingly, CNC machining and injection molding are also being integrated into rapid prototyping processes for producing higher-fidelity parts that more closely resemble the final product.

Moreover, rapid prototyping plays a critical role in custom manufacturing, where flexibility, low-volume production, and quick turnaround are essential. For startups and innovation-driven companies, it allows the realization of unique and complex designs without the need for large-scale tooling or long-term investment.

As a custom manufacturing partner, Minewing leverages over 20 years of engineering and production experience to help clients transition seamlessly from concept to prototype to mass production. With in-house capabilities in 3D printing, precision machining, electronics integration, and material sourcing, we ensure that every prototype not only looks good—but works as intended.

With rapid prototyping, innovation is no longer limited by time or resources. It empowers creators to iterate boldly, test efficiently, and bring better products to life.

Post time: Apr-13-2025