PCBA is the process of mounting electronic components onto a PCB.

We handle all the stages in one place for you.

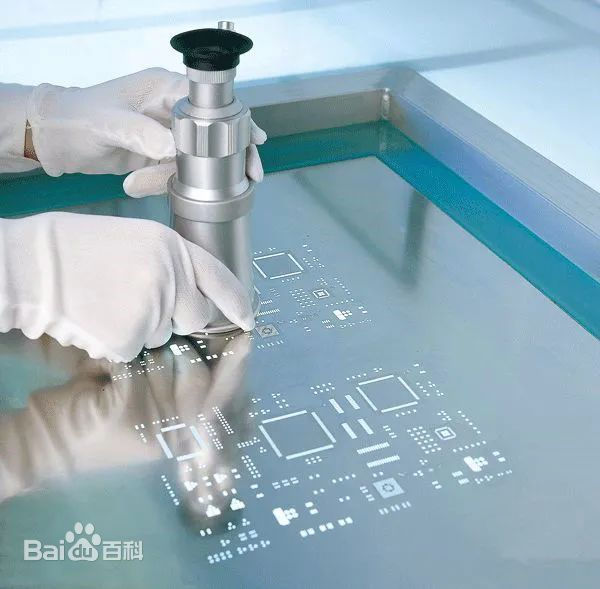

1. Solder Paste Printing

The first step in PCB assembly is the printing of solder paste onto the pad areas of the PCB board. The solder paste consists of tin powder and flux and is used to connect the components to the pads in subsequent steps.

2. Surface Mounted Technology(SMT)

Surface Mounted Technology(SMT components) are placed on solder paste using a bonder. A bonder can quickly and accurately place a component in a specified location.

3. Reflow Soldering

The PCB with the components attached is passed through a reflow oven, where the solder paste melts at high temperature and the components are firmly soldered to the PCB. Reflow soldering is a key step in SMT assembly.

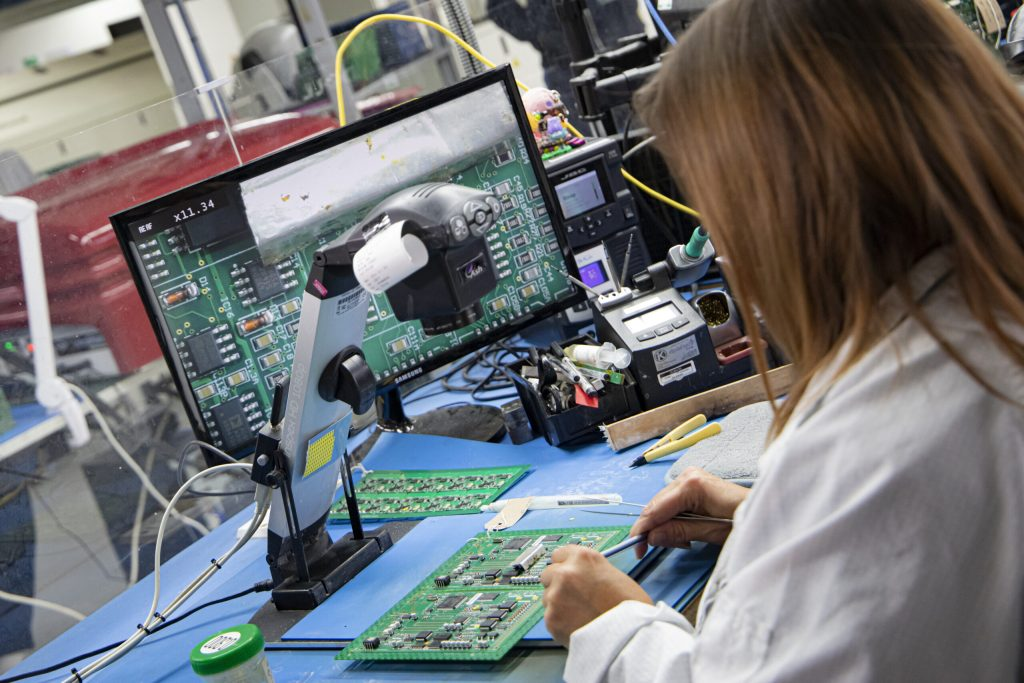

4. Visual Inspection and Automated Optical Inspection (AOI)

After reflow soldering, PCBs are visually inspected or automatically optically inspected using AOI equipment to ensure that all components are soldered correctly and are free of defects.

5. Thru-Hole Technology (THT)

For components that require through-hole technology (THT), the component is inserted into the PCB’s through-hole either manually or automatically.

6. Wave Soldering

The PCB of the inserted component is passed through a wave soldering machine, and the wave soldering machine welds the inserted component to the PCB through a wave of molten solder.

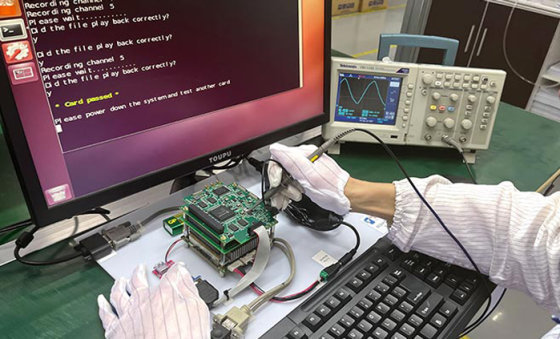

7. Function Test

Functional testing is performed on the assembled PCB to ensure that it works properly in the actual application. Functional testing can include electrical testing, signal testing, etc.

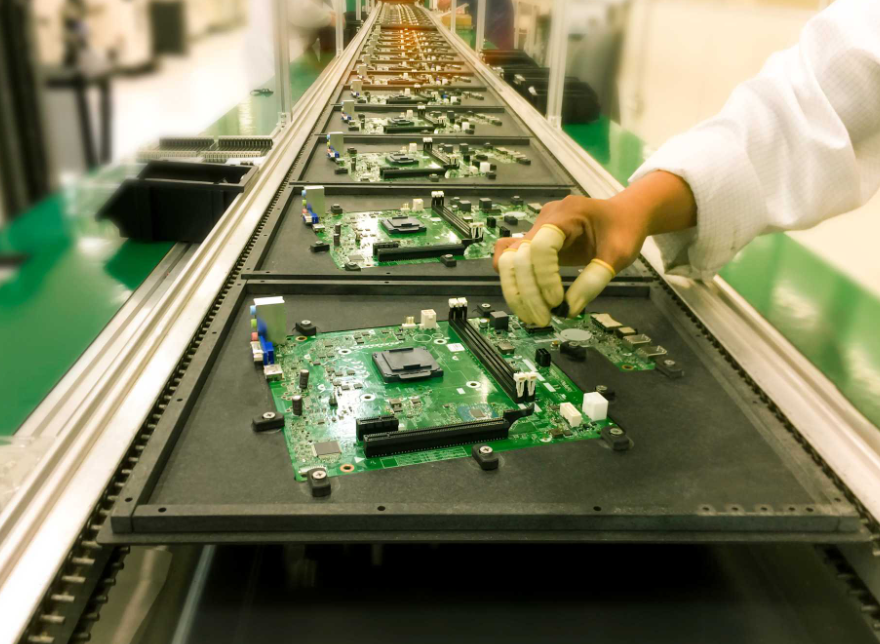

8. Final Inspection and Quality Control

After all tests and assemblies are completed, a final inspection of the PCB is performed to ensure that all components are installed correctly, free of any defects, and in accordance with the design requirements and quality standards.

9. Packaging and Shipping

Finally, the PCB that have passed the quality check are packaged to ensure that they are not damaged during transportation and then shipped to customers.

Post time: Jul-29-2024