EMS mayankho kwa Printed Circuit Board

Kufotokozera

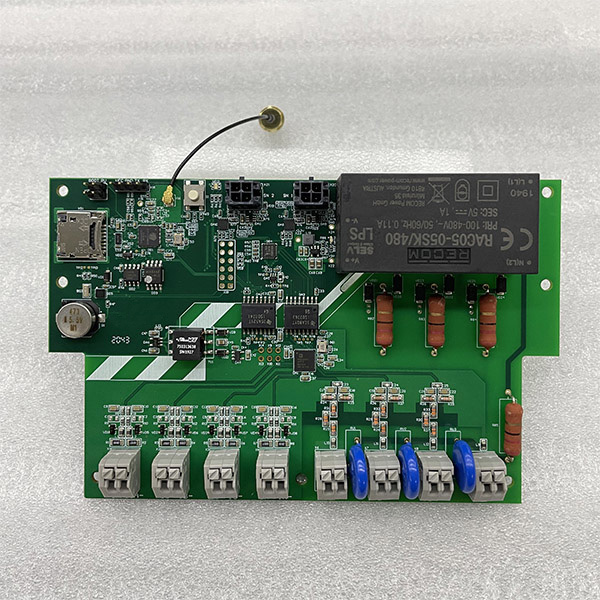

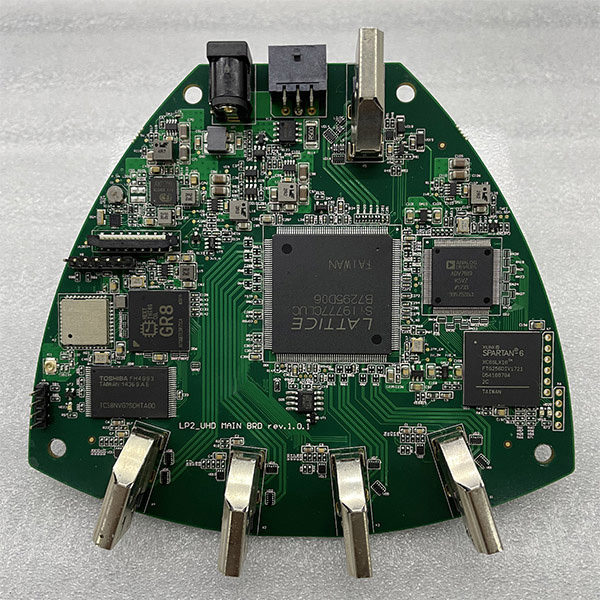

Zokhala ndi chipangizo cha SPI, AOI, ndi X-ray cha mizere 20 ya SMT, 8 DIP, ndi mizere yoyesera, timapereka ntchito zapamwamba zomwe zimaphatikizapo njira zambiri zolumikizirana ndikupanga PCBA yamagulu angapo, PCBA yosinthika. Laborator yathu yaukadaulo ili ndi ROHS, drop, ESD, ndi zida zapamwamba & zotsika zoyezera kutentha. Zogulitsa zonse zimaperekedwa ndi kuwongolera kokhazikika. Pogwiritsa ntchito makina apamwamba a MES pakuwongolera zopanga pansi pa IAF 16949 muyezo, timagwira ntchito bwino komanso motetezeka.

Mwa kuphatikiza zothandizira ndi mainjiniya, titha kuperekanso mayankho a pulogalamuyi, kuyambira pakupanga pulogalamu ya IC ndi mapulogalamu mpaka kapangidwe kamagetsi kamagetsi. Pokhala ndi chidziwitso pakupanga mapulojekiti azachipatala komanso zamagetsi zamakasitomala, titha kutenga malingaliro anu ndikupangitsa kuti zinthu zenizeni zikhale zamoyo. Popanga mapulogalamu, pulogalamu, ndi bolodi lokha, tikhoza kuyang'anira ntchito yonse yopangira bolodi, komanso zinthu zomaliza. Chifukwa cha fakitale yathu ya PCB ndi mainjiniya, imatipatsa mwayi wopikisana poyerekeza ndi fakitale wamba. Kutengera kapangidwe kazinthu & gulu lachitukuko, njira yokhazikitsidwa yopangira zinthu zosiyanasiyana, komanso kulumikizana kothandiza pakati pa mayendedwe operekera, tili ndi chidaliro chokumana ndi zovuta ndikumaliza ntchitoyo.

| PCBA luso | |

| Zida zokha | Kufotokozera |

| Makina ojambulira laser PCB500 | Kuyika chizindikiro: 400 * 400mm |

| Liwiro: ≤7000mm/S | |

| Mphamvu yayikulu: 120W | |

| Q-kusintha, Udindo wa Ntchito: 0-25KHZ; 0-60% | |

| Makina osindikizira a DSP-1008 | Kukula kwa PCB: MAX: 400 * 34mm MIN: 50 * 50mm T: 0.2 ~ 6.0mm |

| Kukula kwa stencil: MAX: 737 * 737mm Kukula: 420 * 520mm | |

| Kuthamanga kwa scraper: 0.5 ~ 10Kgf / cm2 | |

| Njira yoyeretsera: Kupukuta kowuma, kuyeretsa konyowa, kutsuka pavuvu (lokonzekera) | |

| Liwiro losindikiza: 6 ~ 200mm/mphindi | |

| Kulondola kosindikiza: ± 0.025mm | |

| SPI | Mfundo yoyezera: 3D White Light PSLM PMP |

| Chinthu choyezera: Voliyumu ya Solder paste, dera, kutalika, XY offset, mawonekedwe | |

| Kusintha kwa lens: 18um | |

| Kulondola: XY kusamvana: 1um; Kuthamanga kwakukulu: 0.37um | |

| Kukula kwa mawonekedwe: 40 * 40mm | |

| Liwiro la FOV: 0.45s/FOV | |

| Makina othamanga a SMT SM471 | Kukula kwa PCB: MAX: 460 * 250mm MIN: 50 * 40mm T: 0.38 ~ 4.2mm |

| Chiwerengero cha ma shafts okwera: 10 spindles x 2 cantilevers | |

| Kukula kwagawo: Chip 0402(01005 inchi) ~ □14mm(H12mm) IC,Cholumikizira(lead phula 0.4mm),※BGA,CSP(Tin ball spacing 0.4mm) | |

| Kukwera kolondola: chip ± 50um@3ó/chip, QFP ± 30um@3ó/chip | |

| Liwiro lokwera: 75000 CPH | |

| Makina othamanga a SMT SM482 | Kukula kwa PCB: MAX: 460 * 400mm MIN: 50 * 40mm T: 0.38 ~ 4.2mm |

| Chiwerengero cha ma shafts okwera: 10 spindles x 1 cantilever | |

| Kukula kwagawo: 0402(01005 inchi) ~ □16mm IC,Cholumikizira(lead phula 0.4mm),※BGA,CSP(Tin ball spacing 0.4mm) | |

| Kukwera kolondola: ± 50μm@μ+3σ (malinga ndi kukula kwa chip) | |

| Liwiro lokwera: 28000 CPH | |

| HELLER MARK III Ng'anjo ya nayitrogeni reflux | Malo: Magawo 9 otentha, 2 malo ozizira |

| Gwero la kutentha: Mpweya wotentha | |

| Kuwongolera kutentha: ± 1 ℃ | |

| Kuchuluka kwa chipukuta misozi: ± 2 ℃ | |

| Kuthamanga kwa orbital: 180-1800mm / min | |

| M'lifupi mwake: 50-460mm | |

| AOI ALD-7727D | Mfundo yoyezera: Kamera ya HD imapeza mawonekedwe a gawo lililonse la kuwala kwamitundu itatu komwe kumawunikira pa bolodi la PCB, ndikuyiweruza pofananiza chithunzi kapena magwiridwe antchito a imvi ndi RGB pa mfundo iliyonse ya pixel. |

| Chinthu choyezera: Zolakwika zosindikizira za Solder paste, zolakwika za magawo, zolakwika zolumikizana za solder | |

| Kusintha kwa lens: 10um | |

| Kulondola: XY kusamvana: ≤8um | |

| 3D X-RAY AX8200MAX | Kukula kwakukulu kozindikira: 235mm * 385mm |

| Mphamvu yayikulu: 8W | |

| Mphamvu yamagetsi: 90KV/100KV | |

| Kuyikira Kukula: 5μm | |

| Chitetezo (mlingo wa radiation): <1uSv/h | |

| Wave soldering DS-250 | PCB m'lifupi: 50-250mm |

| Kufalikira kwa PCB kutalika: 750 ± 20 mm | |

| Kuthamanga liwiro: 0-2000mm | |

| Kutalika kwa preheating zone: 0.8M | |

| Chiwerengero cha zone yotenthetsera: 2 | |

| Nambala yoweyula: Mafunde apawiri | |

| Makina a board splitter | Ntchito zosiyanasiyana: MAX: 285 * 340mm MIN: 50 * 50mm |

| Kudula mwatsatanetsatane: ± 0.10mm | |

| Kudula liwiro: 0 ~ 100mm / S | |

| Liwiro la kuzungulira kwa spindle: MAX: 40000rpm | |

| Technology luso | ||

| Nambala | Kanthu | Kuthekera kwakukulu |

| 1 | zinthu zoyambira | Normal Tg FR4, High Tg FR4, PTFE, Rogers, Low Dk/Df etc. |

| 2 | Mtundu wa chigoba cha solder | wobiriwira, wofiira, wabuluu, woyera, wachikasu, wofiirira, wakuda |

| 3 | Mtundu wa nthano | woyera, wachikasu, wakuda, wofiira |

| 4 | Mtundu wa mankhwala apamtunda | ENIG, malata omiza, HAF, HAF LF, OSP, golide wonyezimira, chala chagolide, siliva wonyezimira |

| 5 | Max. kusanjikiza (L) | 50 |

| 6 | Max. kukula kwa unit (mm) | 620*813 (24"*32") |

| 7 | Max. kukula kwa gulu (mm) | 620*900 (24"x35.4") |

| 8 | Max. makulidwe a board (mm) | 12 |

| 9 | Min. makulidwe a board (mm) | 0.3 |

| 10 | Kulekerera makulidwe a board (mm) | T<1.0 mm: +/-0.10mm; T≥1.00mm: +/-10% |

| 11 | Kulolera kulembetsa (mm) | +/-0.10 |

| 12 | Min. makina kubowola m'mimba mwake (mm) | 0.15 |

| 13 | Min. kubowola laser m'mimba mwake(mm) | 0.075 |

| 14 | Max. mbali (kupyolera mu dzenje) | 15:1 |

| Max. mbali (micro-via) | 1.3:1 | |

| 15 | Min. m'mphepete mwa dzenje mpaka mkuwa (mm) | L≤10, 0.15;L=12-22,0.175;L=24-34, 0.2;L=36-44, 0.25;L>44, 0.3 |

| 16 | Min. chilolezo chamkati (mm) | 0.15 |

| 17 | Min. m'mphepete mwa dzenje mpaka m'mphepete mwa dzenje (mm) | 0.28 |

| 18 | Min. dzenje m'mphepete mwa mzere wa mbiri (mm) | 0.2 |

| 19 | Min. mkuwa wamkati mpaka mbiri ya sapce (mm) | 0.2 |

| 20 | Kuloledwa kulembetsa pakati pa mabowo (mm) | ± 0.05 |

| 21 | Max. kumaliza mkuwa makulidwe (um) | Mtundu Wakunja: 420 (12oz) Mkati mwake: 210 (6oz) |

| 22 | Min. kufufuza m'lifupi (mm) | 0.075 (3mil) |

| 23 | Min. kufufuza malo (mm) | 0.075 (3mil) |

| 24 | Makulidwe a chigoba cha solder (um) | ngodya ya mzere:> 8 (0.3mil) Pamkuwa:> 10 (0.4mil) |

| 25 | ENIG golide makulidwe (um) | 0.025-0.125 |

| 26 | ENIG makulidwe a nickle (um) | 3-9 |

| 27 | Sterling siliva makulidwe (um) | 0.15-0.75 |

| 28 | Min. HAL makulidwe a malata (um) | 0.75 |

| 29 | Kumizidwa kwa malata (um) | 0.8-1.2 |

| 30 | Kukhuthala kwa golide wokhuthala (um) | 1.27-2.0 |

| 31 | Kukhuthala kwa chala chagolide (um) | 0.025-1.51 |

| 32 | golden chala plating nickle makulidwe(um) | 3-15 |

| 33 | makulidwe a golide wonyezimira (um) | 0,025-0.05 |

| 34 | makulidwe a nickle wagolide wonyezimira (um) | 3-15 |

| 35 | kukula kwa mbiri (mm) | ± 0.08 |

| 36 | Max. kukula kwa dzenje la solder mask (mm) | 0.7 |

| 37 | BGA pansi (mm) | ≥0.25 (HAL kapena HAL Yaulere: 0.35) |

| 38 | Kulekerera kwa tsamba la V-CUT (mm) | +/-0.10 |

| 39 | Kulekerera kwa V-CUT (mm) | +/-0.10 |

| 40 | Kulekerera kwa bevel angle yagolide (o) | +/-5 |

| 41 | Kulekerera kwa Impedence (%) | +/- 5% |

| 42 | Kulekerera kwa Warpage (%) | 0.75% |

| 43 | Min. kukula kwa nthano (mm) | 0.1 |

| 44 | Moto woyaka moto | 94v-0 |

| Zapadera za Via mu pad mankhwala | Kukula kwa dzenje lomata utomoni (min.) (mm) | 0.3 |

| Kukula kwa dzenje (max.) (mm) | 0.75 | |

| Makulidwe a bolodi lomata utomoni (min.) (mm) | 0.5 | |

| Makulidwe a bolodi lolumikizidwa ndi utomoni (max.) (mm) | 3.5 | |

| Resin plugged maximum aspect ratio | 8:1 | |

| Utoto umatsekera pang'ono bowo (mm) | 0.4 | |

| Kodi mungasiyanitse kukula kwa bowo pa bolodi limodzi? | inde | |

| Bwalo la ndege lakumbuyo | Kanthu | |

| Max. kukula kwa pnl (kumaliza) (mm) | 580*880 | |

| Max. kukula kwa gulu (mm) | 914 × 620 | |

| Max. makulidwe a board (mm) | 12 | |

| Max. kusanjikiza (L) | 60 | |

| Mbali | 30:1 (Min. dzenje: 0.4 mm) | |

| Mzere waukulu/danga (mm) | 0.075/ 0.075 | |

| Kukhoza kubowola kumbuyo | Inde | |

| Kulekerera kubowola kumbuyo (mm) | ± 0.05 | |

| Kulekerera mabowo osindikizira (mm) | ± 0.05 | |

| Mtundu wa mankhwala apamtunda | OSP, siliva wokongola, ENIG | |

| Rigid-flex board | Kukula kwa dzenje (mm) | 0.2 |

| Makulidwe a dielectrical (mm) | 0.025 | |

| Kukula kwa gulu logwirira ntchito (mm) | 350x500 | |

| Mzere waukulu/danga (mm) | 0.075/ 0.075 | |

| Wolimba | Inde | |

| Flex board layers (L) | 8 (4plys of flex board) | |

| Ma board olimba (L) | ≥14 | |

| Chithandizo chapamwamba | Zonse | |

| Flex board mkati kapena kunja wosanjikiza | Onse | |

| Zapadera pazogulitsa za HDI | Kukula kwa dzenje la laser (mm) | 0.075 |

| Max. makulidwe a dielectric (mm) | 0.15 | |

| Min. makulidwe a dielectric (mm) | 0.05 | |

| Max. mbali | 1.5:1 | |

| Kukula kwa Pad Pansi (pansi pa micro-via) (mm) | Kukula kwa dzenje + 0.15 | |

| Pamwamba Pad kukula (pa micro-via) (mm) | Kukula kwa dzenje + 0.15 | |

| Kudzaza mkuwa kapena ayi (inde kapena ayi) (mm) | inde | |

| Kudzera mu kapangidwe ka Pad kapena ayi (inde kapena ayi) | inde | |

| Utoto wokwiriridwa dzenje wolumikizidwa (inde kapena ayi) | inde | |

| Min. kudzera kukula akhoza kudzazidwa mkuwa (mm) | 0.1 | |

| Max. nthawi stack | wosanjikiza uliwonse | |