Kwintsimi yokwenziwa kweprototype, i-CNC machining kunye ne-silicone yokuvelisa i-silicone yokuvelisa iindlela ezimbini ezisetyenziswa ngokuqhelekileyo, nganye inikezela ngeenzuzo ezihlukeneyo ngokusekelwe kwiimfuno zemveliso kunye nenkqubo yokuvelisa. Ukuhlalutya ezi ndlela kwiimbono ezahlukeneyo-ezifana nokunyamezela, ukugqiba umphezulu, amazinga okuguqulwa, isantya sokuvelisa, indleko, kunye nokuhambelana kwezinto-ubonelela ngeembono ezixabisekileyo zokukhetha ubuchule obufanelekileyo.

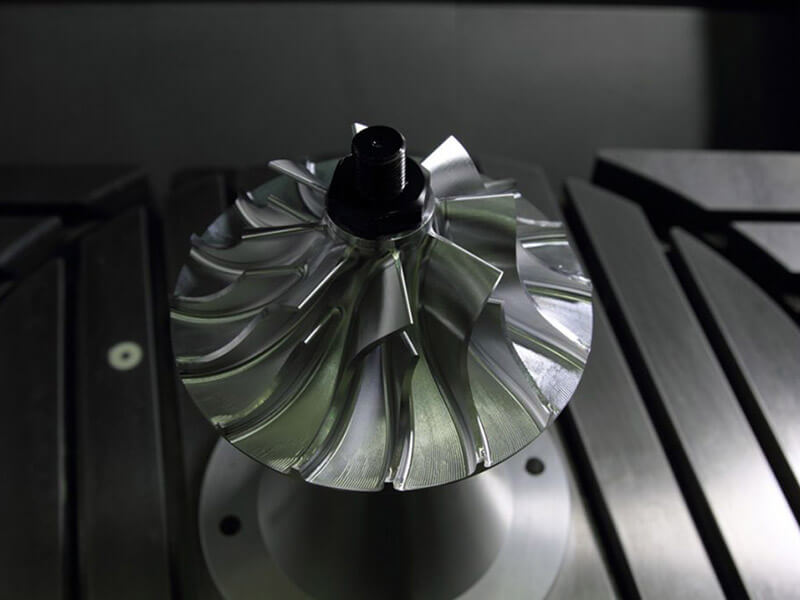

Ukunyamezelwa kweMveliso kunye nokuChaneka:

I-CNC Machining idume ngokuchaneka kwayo okuphezulu, kunye nokunyamezelana okuqinileyo njenge-± 0.01 mm, kuyenza ibe lolona khetho lufanelekileyo kwiijometri ezintsonkothileyo okanye iinxalenye ezifuna ukuchaneka okuneenkcukacha. Oku kubaluleke kakhulu kwiindibano zoomatshini okanye kwiiprototypes ezisebenzayo apho ukuchaneka kubalulekile. Ngokwahlukileyo, imveliso ye-silicone yokubumba inika ukuchaneka okuncinci, kunye nokunyamezela okuqhelekileyo malunga ne-± 0.1 mm. Nangona kunjalo, eli nqanaba lokuchaneka lihlala lanele kwiimveliso ezininzi zabathengi okanye iiprototypes zakwangoko.

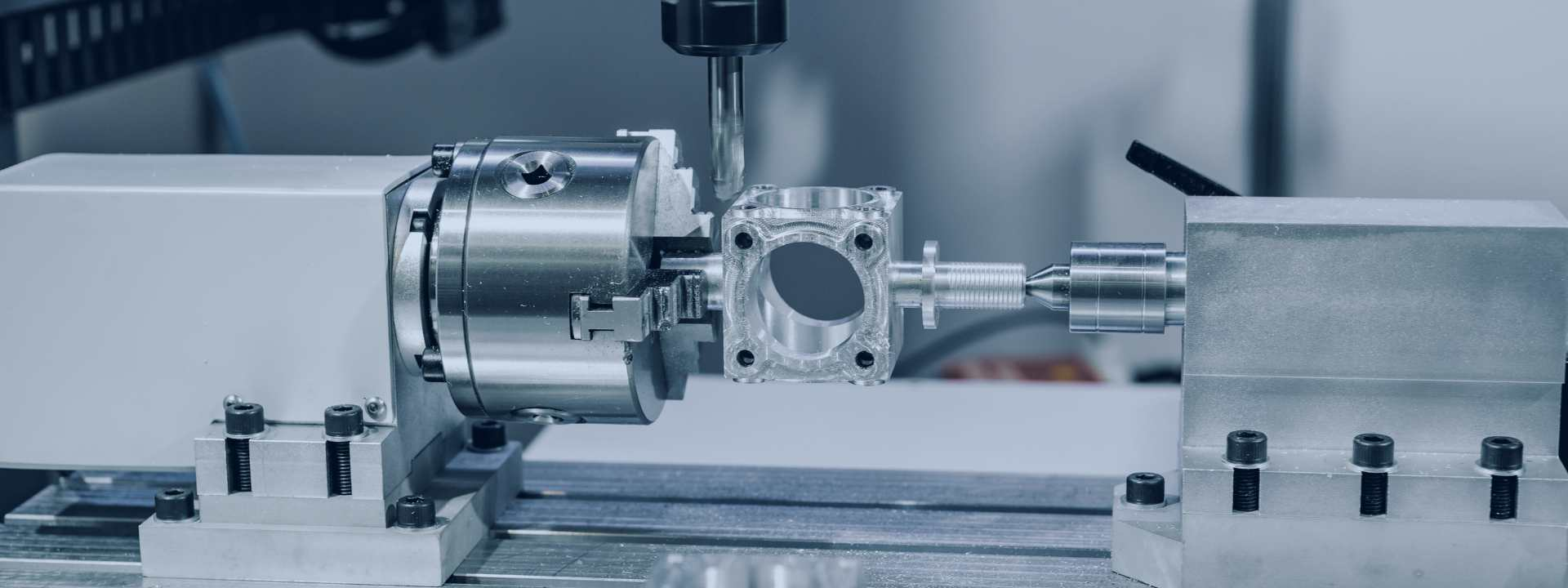

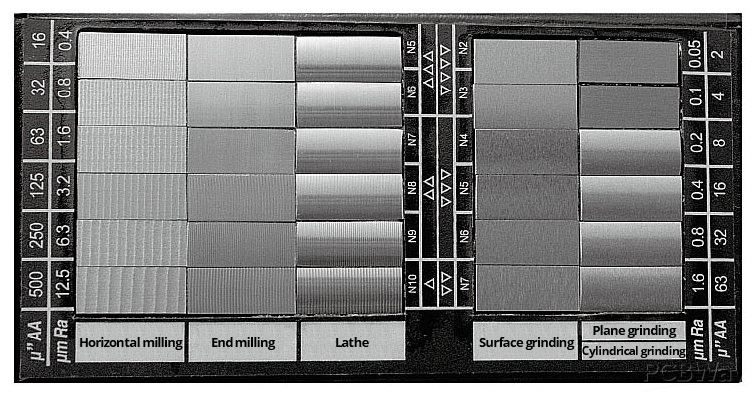

UkuGqiba komphezulu kunye noMgangatho wobuhle:

Umatshini we-CNC uvelisa ukugqitywa okugqwesileyo komphezulu, ngakumbi kwiintsimbi kunye neeplastiki eziqinileyo. Iinketho zasemva kokulungiswa okunje nge-anodizing, ukuqhushumba kweentsimbi, okanye ukupolisha kunokunyusa umgangatho womphezulu, ukunikezela ngenkangeleko ephezulu kunye nokuziva, okuyimfuneko kwiprototypes yobuhle. Kwelinye icala, ukubumba kwe-silicone kunokuphindaphinda ukuthungwa kunye neenkcukacha ezintle kakuhle kodwa zihlala zifuna ukugqitywa okwesibini ukuze kufezekiswe ukugudiswa komphezulu okuthelekisayo, ngakumbi ngezinto ezithambileyo ezifana neerabha okanye ii-elastomers.

Utshintsho kunye neMfezeko yoLwakhiwo:

I-CNC machining, iyinkqubo yokuthabatha, inika imfezeko yolwakhiwo oluphezulu kunye noguquko oluncinci kuba akukho kufudumala okanye unyango olubandakanyekayo. Oku kuyenza ilungele iindawo ezifuna ukugcina uzinzo lwe-dimensional, ngakumbi phantsi komthwalo okanye uxinzelelo. Ukuveliswa kokubumba kwe-silicone, nangona kunjalo, kubandakanya ukuphosa izinto ezinokuthi zibe nokuncipha kancinci okanye i-warping ngexesha lenkqubo yokunyanga, ezinokuchaphazela ukuchaneka kwemveliso yokugqibela, ngakumbi kumacandelo amakhulu okanye abanzi.

Isantya seMveliso kunye nexesha lokuKhokela:

Xa kuziwa kwisantya semveliso, ukubumba i-silicone kunenzuzo ebalulekileyo ekudaleni iiprototypes ezininzi kwixesha elifutshane. Nje ukuba ukungunda kulungiswe, imveliso inokunyuka ngokukhawuleza, iyenze ilungele ukwenziwa kweebhetshi ezincinci kunye novavanyo lwentengiso. Umatshini we-CNC, ngelixa ucotha kwimveliso yomthamo ophezulu, unikezela amaxesha okutshintsha ngokukhawuleza kwiindawo ezingatshatanga okanye ezinobungakanani obuphantsi, okwenza kube lolona khetho lungcono kwiiprototypes zokuqala okanye xa ukuphindaphinda koyilo rhoqo.

Iindleko kunye nokuSetyenziswa kwezinto:

I-CNC machining ibandakanya iindleko eziphezulu ngenxa yeendleko zemathiriyeli ekrwada (ingakumbi isinyithi) kunye nexesha lomatshini elifunekayo kwiindawo ezinzima. Ukongeza, iinkqubo ze-CNC zinokukhokelela kwinkcitho yezinto eziphathekayo, ngakumbi kwimveliso ekhuphayo apho iinxalenye ezibalulekileyo zezinto zisuswa. Ngokwahlukileyo, imveliso ye-silicone yokubumba inexabiso elithe kratya kwi-low-volume runs, njengoko iindleko zezinto eziphathekayo ziphantsi, kwaye iimbumba zingaphinda zisetyenziswe. Nangona kunjalo, ukubumba i-silicone kufuna utyalo-mali olungaphambili lwezixhobo, ezinokuthi zingathetheleleki ngezixa eziphantsi kakhulu okanye iiprototypes enye.

Ukuqukumbela, ukwenziwa komatshini we-CNC kunye ne-silicone yokubumba zombini zidlala indima ebalulekileyo kwimveliso yeprototype, nganye ifanele izigaba ezahlukeneyo zophuhliso lwemveliso. I-CNC machining ikhethwa ngokuchaneka okuphezulu, okuqinileyo, kunye neprototypes eneenkcukacha, ngelixa ukubunjwa kwe-silicone kunika isisombululo esikhawulezayo, esinexabiso elithe kratya le-flexible, i-ergonomic, okanye i-multi-unit unit. Ukuqonda iimfuno ezithile zeprototype, kubandakanya ukunyamezela, ukugqitywa komphezulu, umthamo wemveliso, kunye neemfuno zezinto eziphathekayo, kubalulekile ekukhetheni indlela efanelekileyo yeprojekthi yakho.

Ixesha lokuposa: Oct-23-2024